What is a Servo Motor?

A servo motor is a high technology electrical device responsible for rotating the parts of the machinery with great precision and high accuracy.

How is Servo Motor Helpful?

The servo motor can allow you to move the output shaft to a particular angle. Besides, the acceleration and velocity that become part of the servo motor are impossible with the other machines. Thus, providing this machine with a competitive advantage that is not part of the other devices.

Types of Servo Motor:

A servo motor can have multiple types, including an AC servo motor, DC servo motor, brushless DC servo motor, positional rotation servo motor, continuous rotation servo motor, and linear servo motor. Each of these motor types is different when it comes to the benefits it provides. So, you will have to analyze each of these before buying a specific one. Be sure to keep your requirements under consideration before getting to a particular servomotor from the ones mentioned here.

Besides, there are multiple brands of the servomotor available in the market too. You can purchase the Fanuc Servo drive or choose a Mitsubishi servo motor, depending on the functions you want your engine to perform.

Working Principle:

Pulse Width Modulation Principle is the driving force behind the working of the servo motor. This angle of rotation is directly proportional to pulse application on its control pin based on the principle.

How It Works:

Although Pulse Width Modulation Principle is the driving force behind it, its works are a bit detailed. We will be sharing it here in this section of the article. You can consider it to be working for the Fanuc Servo drive or Mitsubishi Servo Motor.

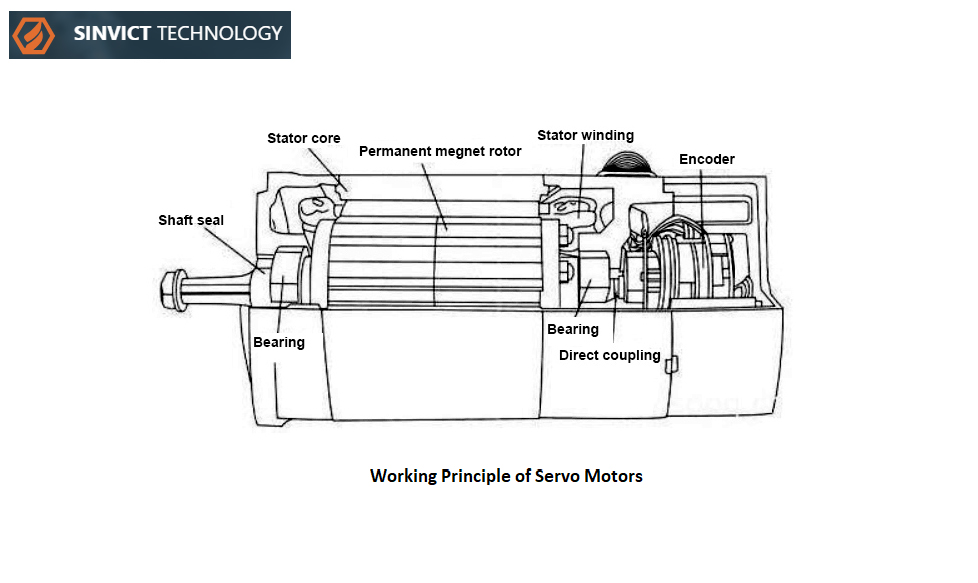

The motor is a closed-loop servomechanism, which uses the feedback for its positioning and motion. An input signal is provided to the engine to get the desired output level. Both these phenomena working together operate the servomotor in its true sense.

In this motor, there is a mechanism for generating the error signal, which helps set the engine’s exact position at the right point. Although it is the position that the motor determines and keeps the explanation simple, we are holding the position as the only point to be considered during the working.

In a typical motor, we signal the engine describing the position that we want the motor to be in. Besides, speed and position feedback is made part of the output based on the encoding method. After the execution, the difference between the commanded production and the actual production is measured. This value is known as the error, and the motor generates an error signal to rectify this difference. Because of this error signal, the motor’s movement occurs in the direction, which could make the output shaft move to the correct position based on your needs.

With the output shaft movement, there comes a time when the error signal reduces to zero. This is the time when the machine stops.

In a Fanuc Servo drive or Mitsubishi servo motor, the speed and precision can be handled quite adequately. The shaft position is converted into the electrical signals by the potentiometer, which is part of the gadgets. So, the above process is executed using the electrical signals that your machine receives.

Controlling of Servomotor:

The potential of movement of the servo meter is 180 degrees at maximum. It can move to 90 degrees in each direction, making a complete linear movement. In a mechanical servomotor, it is not possible to go beyond this level.

Wires in a Servo Motor:

You might not have much technical insight, but knowing a few basic things about the servo motor would be essential in highlighting the functioning and the working model of these motors under consideration. So, let us have a look.

There are three wires in a servo motor. These include the positive, neutral, and control wire. The pulse given to the engine is through the controlled wire. There is a difference of 20mm in each of the vibrations. The width of this pulse determines the shaft position and helps in undergoing the entire process that we have highlighted above.

Uses:

There are multiple usages of this servo motor:

- Joining the servomotor at every joint of a robot can give precise angular movement, making the robots look perfect.

- Using these motors in the conveyor belts ensures precise movement in different stages.

- The camera lens is corrected with a servo motor’s help, resulting in sharpening out the image focus.

- Another use of these motors is in the solar tracking system. The movement of the solar panels with the direction of the sun ensures the highest power generation.